Advantages of using concrete leveling spacers:

- Reducing the cost of concreting.

- Reduce execution time.

- Reducing the weight of the building.

- Creating an index for the amount of concreting.

- Creating the same concrete thickness and cover on the underfloor heating reinforcements and pipes.

- Prevent moisture and air from reaching, which causes oxidation and increase in volume and cracking.

- Creating springs for regular concreting.

- Assurance of the supervising engineer during concreting for the mandatory and standard coverage of concrete on all surfaces of the roof and reinforcements.

Advantages of using adjustable alignment spacers

- Creating adjustable and precise alignment in flooring.

- Creating a sloping and adjustable level on the roof and during concreting of the structure.

- Creating a point level to determine the concreting level on the reinforcements.

- Creating a point level for the index of the amount of flooring in floors with foam concrete or pumice .

- The speed of leveling in an area of 100 meters is less than half an hour

- Removal of subsequent slopes on the roof .

- Removal of excess materials for sloping and reducing the weight of the building.

- Elimination of time spent on sloping and mortaring the roof.

- Elimination of construction costs and subsequent labor for roof slope and floor leveling.

Advantages of using concrete leveling spacers

1-1 Reducing the cost of concrete:

The meaning of reducing the cost of concreting is that it can be seen that for each roof of around 100 meters, approximately 2 cubic meters of concrete is ordered, which in itself brings a cost that actually, despite the existence of an index to determine the amount of concrete poured in There is no need to order additional concrete for the roof, and the amount of concrete can be ordered more precisely.

Correct way:

By using concrete leveling spacers that allow you to adjust the thickness of the concrete on the reinforcements based on the regulations of that system, you are much more accurate in calculating the concrete order and save on the cost of buying additional concrete

1-2 Reduced execution time:

During concreting, it is often observed that contractors and even supervising engineers do not have the ability to determine the thickness of concrete on reinforcements due to non-compliance with standards and indicators, and they always obsessively try to spend more time on troweling. Smoothing the concrete without indexing causes more time during concreting.

Correct way:

The use of concrete leveling spacers can determine the thickness of the concrete on the reinforcements well, and we can see the standard thickness on the entire surface of the roof on the reinforcements, neither less nor more. Sensitivity decreases.

1-3 Reducing the weight of the building:

According to the advantage number 1-1, which refers to the reduction of the cost of concreting, naturally, when the order quantity of additional concrete decreases, the building will also get rid of the extra weight and load. We know that each cubic meter of concrete weighs 2400 kg, and if we have an additional order of 2 cubic meters of concrete for a floor of about 100 square meters, the contractors and engineers will certainly add that concrete to the roof to ensure that the cover on the reinforcements does not decrease. And finally, we will see that if we consider the amount of 2 cubic meters of concrete to be 5 tons and the number of floors of the building is 5 floors, the weight of the building will be about 25 tons extra, which is the case in more than 90% of the buildings in It happened now.. so easily.

Correct way:

When you are sure of the standard thickness of concrete according to the regulations with the presence of concrete leveling spacers, there is no need to order additional concrete to remove the doubt of reducing or increasing the concrete cover and it prevents the building from becoming heavy.

1-4 Creating an index for the amount of concreting:

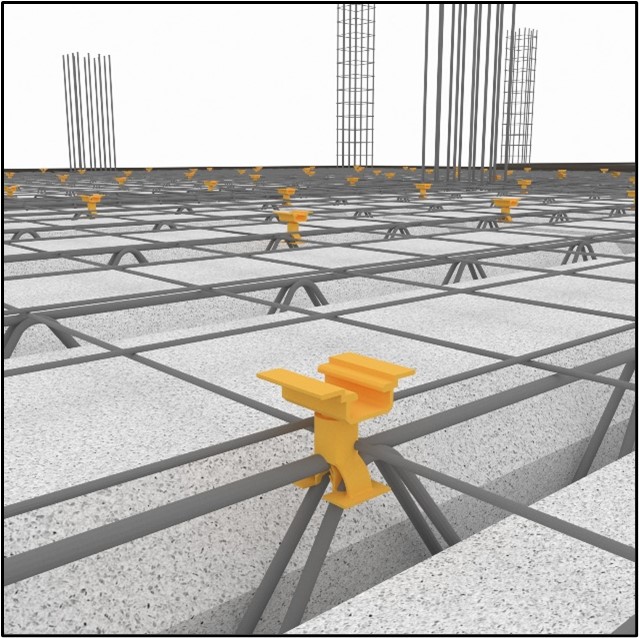

As it was said at the time of concreting, when the concrete covers the reinforcements, it is no longer possible to determine the thickness of the concrete according to the regulations of that roof, and the concrete is applied in a wavy form on the reinforcements. Therefore, there is a need for an index to determine the thickness of concrete.

Correct way:

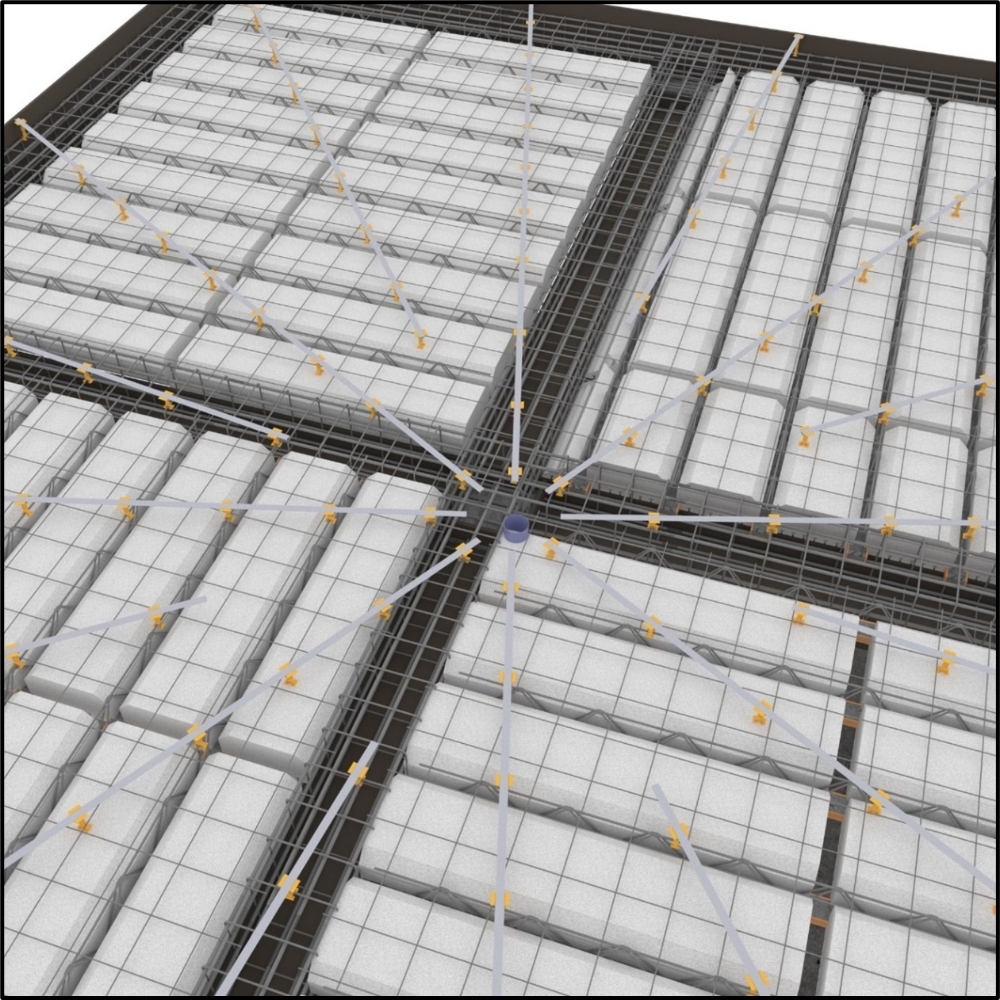

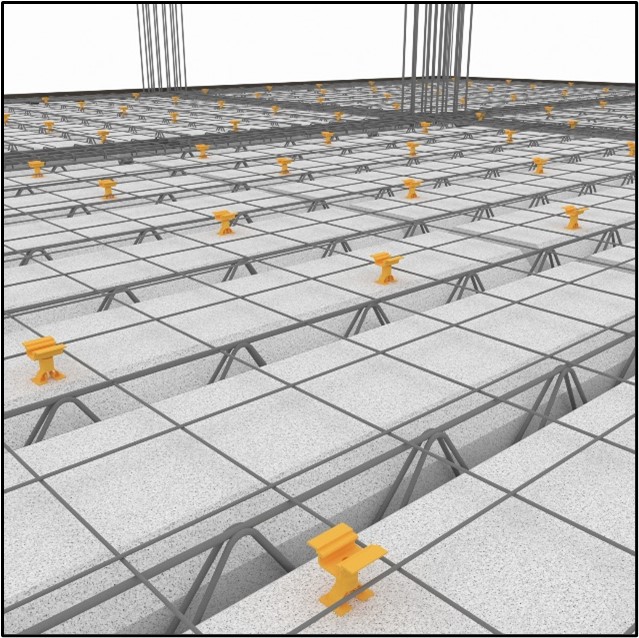

With the presence of concrete leveling spacers, an index and a measure for the thickness and cover of the concrete is formed on the reinforcements at the roof level, according to which you determine the height of the concrete.

1-5 Creating the same concrete thickness and cover on the underfloor heating reinforcements and pipes:

Every regulation of the common roofs has determined a specific thickness for the amount of concrete on the roof reinforcements, which is not necessarily followed in practice during concreting due to the lack of standards. Therefore, there is a need for an index for the amount of concrete thickness to have a certain thickness on the surface of the reinforcements. On floor heating pipes, the amount of concrete is defined as a standard, but this standard is not followed during concreting, and sometimes the thickness of concrete on floor heating pipes is increased, which leads to a decrease in heat transfer to the surface.

Correct way:

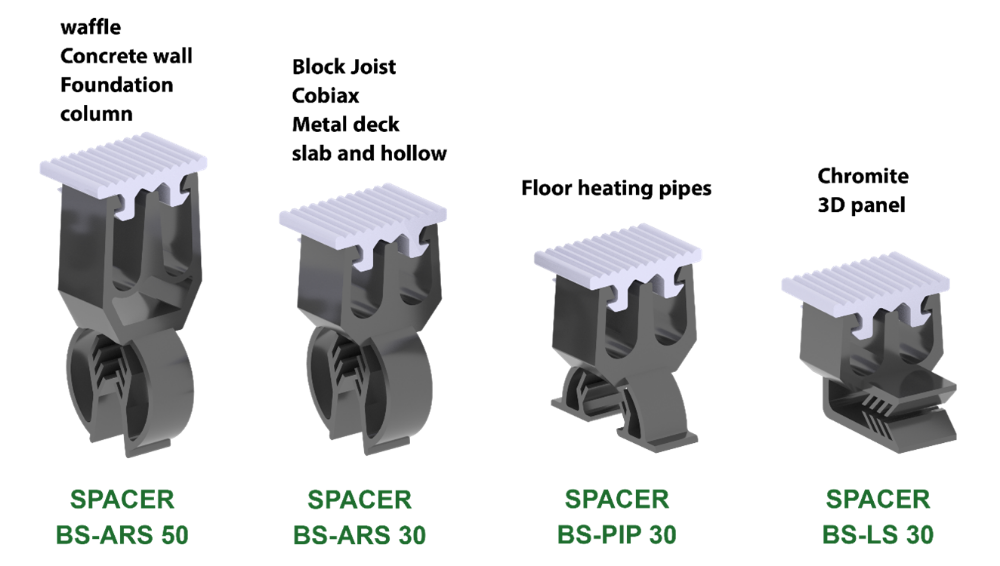

The concrete leveling spacers are designed according to the different regulations of the common executive roofs, and by using them, the amount of concrete thickness can be determined on the reinforcements or floor heating pipes in a standard way.

1-6 Preventing moisture and air from reaching, which causes oxidation and increase in volume and cracking:

One of the most important weaknesses of reinforced concrete structures is the influence of environmental factors. Oxygen and moisture from the environment can penetrate into the concrete and accelerate the corrosion of the rebar and reduce the useful life of the structure. Every 2 mm reduction of the required concrete cover reduces the useful life of the structure by 5 years.

Correct way:

Concrete leveling spacers allow your structure to properly cover the standard concrete cover on the reinforcements and prevent oxygen and moisture from reaching the rebars and prevent the reinforcements from rusting and rotting.

1-7 Creating springs for regular concreting:

Usually, during concreting, contractors start pouring and smoothing concrete from a corner of the roof in an irregular manner, and sometimes they are confused about which direction to go, and it can be seen that the controller of the concrete rig decides to move the rig pipe to What direction should he take.

Correct way:

Installing concrete leveling profiles on the reinforcements parallel to each other allows your structure to show the entire roof as a grid, and during concreting, you fill these grids with concrete one after the other.

1-8 The assurance of the supervising engineer during concreting for the mandatory and standard coverage of concrete on all surfaces of the roof and reinforcements:

After the completion of concreting, building supervisors have no basis to control the thickness of concrete on the reinforcements, and only by looking at the concreted surface and without ensuring the correctness of the standard concrete cover on the reinforcements, they can fix the work even with undetectable defects. They confirm.

Correct way:

After installing the concrete leveling spacers, the engineers are sure that the concrete coating on the reinforcements is completely smooth and without too much or too little, and other non-professional contractors and builders cannot be responsible by not working and spending less money in this field. and escape from the standard concrete quantity and by thinning the concrete on the reinforcements, convince the supervising engineer that the concreting is done correctly.

Note: It has been seen that at the end of concreting on the roof, there is less concrete and even for 1 cubic meter, another mixer should be ordered. But in these cases, non-professional contractors and owners try to transfer concrete from other parts of the roof that they have concreted to make up for the deficit of borrowing from the concrete cover in other places, which weakens the concrete cover of the concrete roof. And it falls below the standard and the structure becomes weak and defective in those places, but by installing concrete leveling spacers, it is not possible to reduce or increase the amount of concrete covering on the reinforcements, and it is no longer possible

Advantages of using adjustable alignment spacers

1-1 Creating adjustable and precise alignment in flooring:

Floor leveling to create a certain level of concrete for flooring cannot be done in a very precise traditional way and often needs to be reconstructed if ceramic or carpet and parquet are needed. The substrate and materials mentioned must be implemented precisely and of course with the cost of labor and materials again, so the exact balance is very important.

Correct way:

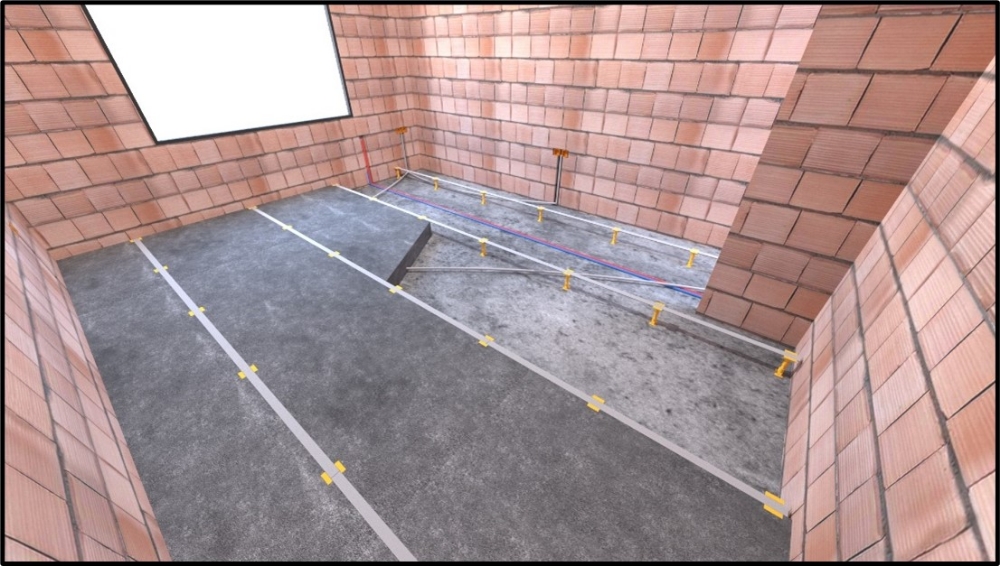

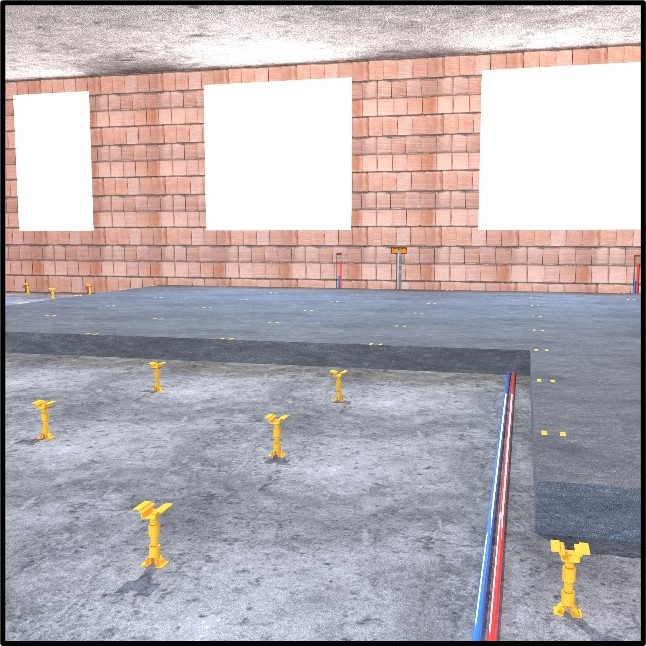

By using the leveling profiles along with the standard leveling adjustable spacers, a 100 meter unit can be leveled in less than 30 minutes with millimeter accuracy and with a laser level, and it is certain that we will see a perfectly level floor.

1-2 Creating a sloping and adjustable level on the roof and during concreting of the structure:

Sloping the roof is always a time-consuming and costly task, and at the same time it makes the structure heavier. After concreting the roof, it has always been a concern to transfer water to the outlet correctly, which has additional time, cost and burden for the structure. In traditional leveling, first by using bricks and mortar, the slope towards the water outlet is implemented in many lines around the water outlet, and then the inside of the lines is filled with pumice and mortar.

Correct way:

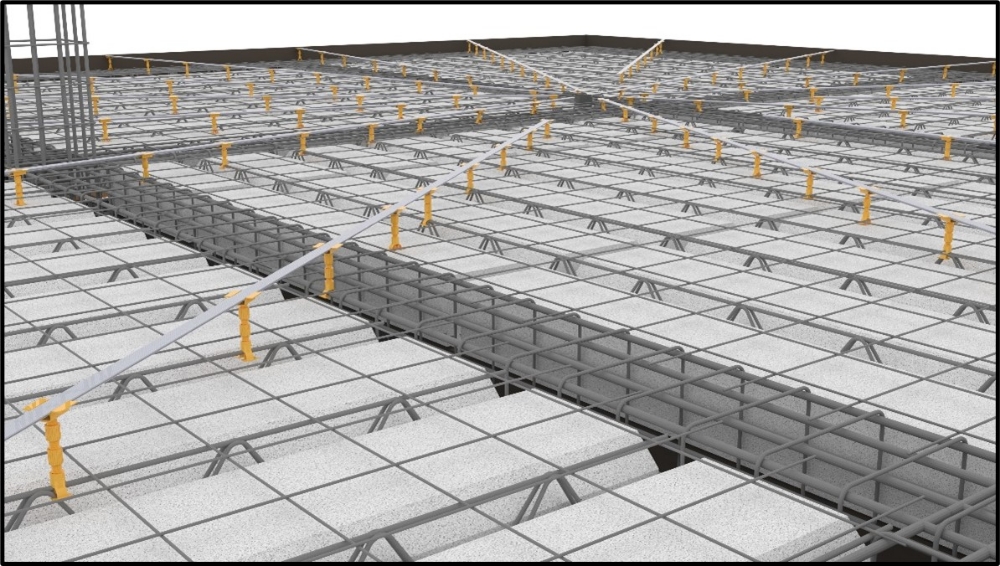

By using standard level profiles and spacers, the roof can be sloped before structural concreting and on the roof reinforcements and foam block or any system of common roofs, the slope can be implemented towards the water outlet pipes. The concreting of the sloped roof has also been done and there is no need to re-slope at the expense of time and money.

1-3 Creating a point level to determine the concreting level on the reinforcements:

Traditionally, during the concreting of the structure, there is no basis for leveling points on the reinforcements, and concreting is done without a standard index, and the concrete is wavy, and this issue is not acceptable in terms of regulations, and it is considered a big flaw, which practically in structures It is ignored while running.

Correct way:

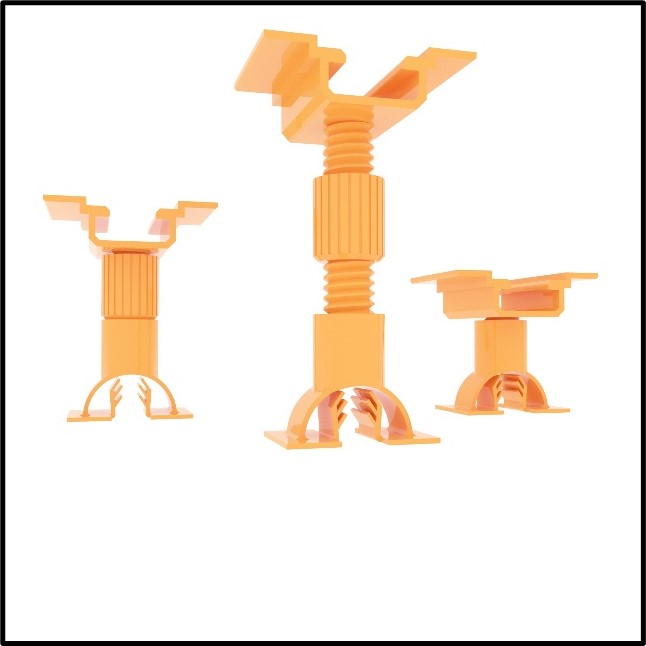

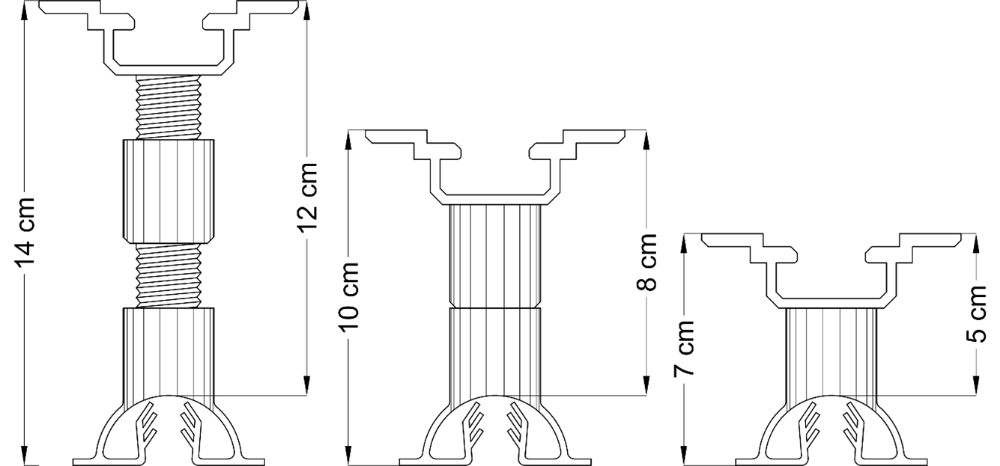

Standard spacers alone have the possibility to use them for point alignment and can be adjusted from 5 cm to 15 cm and even higher. Leveling standards can be mounted on the reinforcements and can be placed on a flat surface, and by rotating, they are adjusted to the required level of the edge of the final concrete and control the concreting of the structure to create a standard cover according to the regulations.

1-4 Creating a point level for the index of the amount of flooring in floors with foam concrete or pumice:

In some cases, in the flooring of the floors, the leveling is done as a point, which takes time and money. He adjusts a piece of stone or tile with mortar on the floor to the final floor level that has been determined in advance, and this is repeated at all points of the floor of the unit with a distance of about 1 meter from each other, and this takes at least two days in a 100-meter unit. It also involves construction and labor costs, and then pumice or foam concrete is implemented.

Correct way:

As mentioned in paragraph 1-3, standard leveling spacers are used alone and can perform leveling work on the surface as much as concrete or foam concrete to the required extent, which can now be used on floors or on Roof reinforcements. or on the soil for leveling concrete, or in concreting or foundation, etc.

1-5 The speed of leveling in a 100 meter area is less than half an hour:

Traditional leveling is always time-consuming and expensive, and in a 100-meter unit, in the most optimistic case, it takes two days of work, along with labor and construction costs, which sometimes is not carried out very precisely and correctly, and after that, the floor must be repaired again to be ready for the final coating.

Correct way:

Working with alignment spacers and alignment standards is very simple and fast, and they can be adjusted quickly and using laser light, saving time-consuming traditional alignment costs as well as construction and labor wages, and a simple construction worker can easily and level an area of 100 square meters in less than half an hour.

1-6 Removal of subsequent slopes on the roof:

Eliminating the slope has traditionally benefited the builder and the structure because it adds important factors of cost, time and weight to the structure.

Correct way:

By using standard leveling profiles and spacers, the execution speed increases significantly and the accuracy of the work increases, and at the same time, the cost and time of leveling the levels is significantly reduced.

1-7 Removal of excess materials for sloping and reducing the weight of the building:

In the slope of the roof, the amount of materials is significant, which is usually implemented in two ways: Pumice and foam concrete, which we analyze both in a 100 square meter area.

At first, for both cases, the traditional slope should be done with the time and cost of materials and wages to direct the water to the outlet, which of course has a significant weight.

Implementation with mineral pumice: in case of implementation with pumice, it is 600 to 700 kg per cubic meter, taking into account that we will have pumice at a height of 10 cm per square meter (one tenth of a cubic meter), it weighs about 60 kg per square meter, and also the minimum coverage of 5 A centimeter of mortar weighs 2400 kg per cubic meter, and for a thickness of 5 centimeters (one twentieth of a cubic meter), it weighs about 120 kg per square meter, and in total, with the weight of pumice, we reach 180 kg per square meter.

Execution with foam concrete: Execution with foam concrete is basically a very wrong method for roof slope, which unfortunately has been used by contractors because foam concrete is used only for leveling floors due to its thinness and self-leveling. However, we also analyze this method. Each cubic meter of foam concrete weighs from 400 to 1800 kg, and this weight difference is different compared to the amount of chemical foam and the mixing of the amount of cement in the used spaces, which is used in the floor of the floors from 400 to 800 kg per cubic meter, and in Places like parking lots (not recommended) use 1000 to 1800 kg/m3. In the slope of the roof, at least 1000 kg/m3 density should be used in order to be able to control the slope with this high density, and taking into account that we have a 10 cm high concrete foam cover per square meter, its weight will be equal to 100 kg/m2. and finally due to the fact that after drying, Waterproofing concrete foam does not stick due to many holes, and at least 3 cm on the surface of the concrete foam, which weighs about 80 kg per square meter (one thirty cubic meters of concrete) and In total, with the weight of foam concrete, we will reach the number of 180 kg/m2, which in both cases of pumice and foam concrete in 100 m2 is equivalent to 18 tons of load to the building.

Correct way:

When profile and leveling standard spacers are used for final roof slope, first of all, traditional roof leveling costs, including the cost of materials and work execution fees, are completely eliminated, and the execution time is also completed at the same time as structural concreting. Now we will analyze the weight calculation of the use of standard alignment spacers:

In order to slope with leveling profiles and adjustable standard spacers, the location of the sewage must first be specified, which is specified in all structures before the building reaches the top floor and the roof of the building facilities and water and sewage pipes. For a slope of 1% per 100 square meters, you need to order 3 cubic meters of extra concrete, which is even less than foam concrete and pumice on the roof, which we have calculated:

The weight of 3 cubic meters of concrete, including 2400 kg per cubic meter, is equal to 7200 kg, which is supposed to be spread on the surface of 100 square meters, and when this number is divided by 100, its weight reaches 72 kg per square meter and that's it. If in the pumice and foam concrete system, we had 180 kg for each square meter, these numbers are not comparable, and in the system of level spacers, both in terms of weight, cost and time, it is beneficial in all dimensions .

1-8 Elimination of time spent on sloping and mortaring the roof:

As described in detail in paragraph 7-1, the implementation of leveling until the implementation of the final floor in the traditional system takes at least one week for a 100-meter area. In fact, time is very important in the building and it entails the cost.

Correct way:

The installation of alignment spacers does not require a lot of time and can be quickly adjusted and executed by a simple worker and takes less than half an hour in a 100 meter area.

1-9 Elimination of construction costs and subsequent labor for roof slope and floor leveling:

Cost is the main factor that builders pay a lot of attention to, and as much as they can reduce the cost of a part of the construction and allocate it elsewhere, they will succeed in providing a more acceptable building to the customers and their satisfaction.

Correct way:

The use of leveling spacers and leveling standards facilitate all the costs of leveling and reglagtion in concreting and flooring, and in terms of cost, time and weight, it is beneficial to the structure and the builder. Earn in shopping.

Communication:

0098 910 2530 705

0098 910 2500 175

INSTAGERAM : @veryacity

SITE : www.veryacity.com